Soldering the microcontroller and powering it up - part 5

If the battery holder already has a cable attached, you can use that one.

- #2535

- 10 Nov 2025

If the battery holder already has a cable attached, you can use that one.

The position of the DIP switch doesn’t affect the balance much, so you can place it wherever you prefer.

We'll be marking and drilling holes a few times during this course. If possible, it may be useful to set up a work desk for yourself.

Make sure to solder the breakaway headers at the correct distance from one another , so you can mount the controller on top of them. If you solder them too close or too far apart, desoldering the breakaway headers will be a harder task than what is meant for this course.

We use breakaway headers so our electronics can stay safe and flexible. They let us connect parts together easily, but also snap them apart later without hurting the circuit. This is helpful because we can test things, fix mistakes, or change parts without rebuilding everything. Think of them like LEGO pieces - they click together when we need them and come apart when we don’t.

Attaching the PCB to the clock face is best done with two sets of hands.

You need not confine yourself to the use of drawing tools. You can easily choose an image from the internet, print it out, and stick it to the clock surface. Or maybe you have other ideas of how to customise the clock face?

We used dental floss to draw lines from the clock face diagonals, and drilled the holes where those lines met.

You need not place the clock's arrow hole in the center. As this is a design choice, you can be creative and place it wherever you wish. You can even customise the shape of the clock face as well, so it is not a plain square like ours.

Don’t worry about which electrical contact you connect to the positive or negative output terminals of the speed controller. The cables can always be swapped later.

Do not solder anything to the speed controller.

You need a very short exposed wire to solder to the DIP switch. Try not to strip too much ot it, as it may come in contact with the other end of the switch, effectively bypassing it.

Be careful not to cut the cable too short, as it is a headache to resolder a new one to the battery holder.

Make sure the components are well held in place before soldering. Some soldering station offers clippers that can hold the DIP switch and the PCB; however, you can use a ductype to achieve the same.

While using cardboard to protect the table from solder may look dangerous, solder cools very fast, and the temperature of the soldering gun is much too low to quickly start a fire. It would take deliberate actions to actually cause safety issues with it.

If you screw the bolts too far into the motor, it may stop working. This won’t be an issue later, but if it causes problems now, place a few nuts on the bolt before using it. This will stop the bolt from going too deep into the motor.

There is a way of mounting the drill bits faster and more reliably than what is shown in this video; however, it requires a steady hand and starting the drill while the drill bit is not yet mounted. We decided that it may pose danger for people not yet savvy with the drill, and that it is best to show how it was intended to be mounted. We strongly advise not using faster methods before you are very comfortable handling this tool.

The dip switch is mounted by using the holes that are already placed on the PCB board. Meaning that we don't need to drill any holes for it.

time to plan where everything on the PCB will go. You can rearrange the components as you wish, as long as the wire connections are done correctly after that.

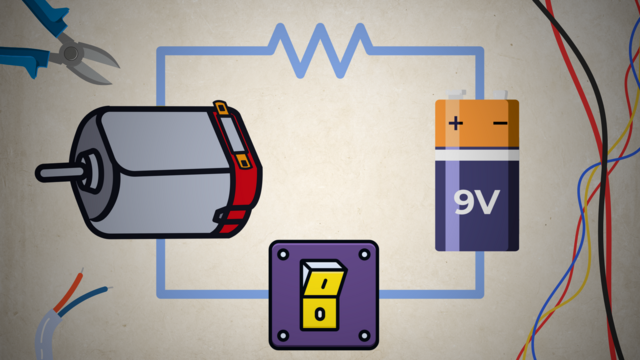

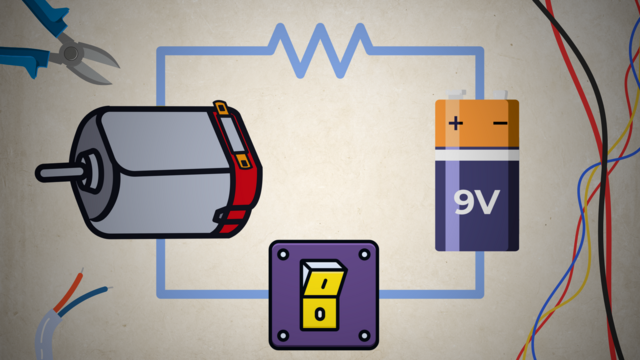

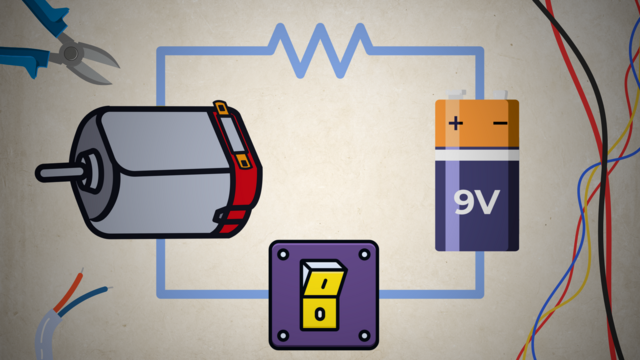

If you’ve connected everything correctly, you can now turn on the motor and control its speed using the potentiometer.

The potentiometer is the small knob on the motor speed controller that you can rotate.

Time to make the final connection and complete the prototype.

To demonstrate that it does not matter where in the circuit we place the switch, we placed it at the negative battery terminal. However, in practice, it is always better to put it near the positive terminal as it lowers the area that can damage your electronics if accidentally touched by other power sources or grounding.

You can notice that the two positive terminals are placed in the middle. That is a common practice that has a few functionalities, like shortening the paths on the PCB, but the main purpose is to lower the chance that the power cables connected directly to the battery are more difficult to touch accidentally.

The motor’s contacts are connected by a wire that is wrapped in a special way. When electricity flows through the wire, it creates a magnetic field that makes the shaft spin. The direction the shaft spins depends on which way the electricity flows. If you switch the wires, the shaft will just spin the other way, and nothing bad will happen. The plus (+) and minus (–) marks on the motor only show which way to connect it if you want the shaft to spin in a certain direction.

Notice that we connect the switch to the red cables and not the black. That is standard practice aimed at minimizing the points through which power can accidentally be connected to other electrical components. Stopping the power near its source is the best way to do it.

Connecting the other side of the motor directly to the battery will turn it on, but we want a way to control when we turn it on without having to disconnect and reconnect cables constantly. For that reason, we added a switch between one of the connections from the motor to the battery. It may seem easier to use a larger switch, but the DIP switch is meant to be soldered to a PCB, and that is what we'll do in the end.

It doesn’t matter if you connect the wire to the positive (cathode) or the negative (anode) terminal of the battery.

Note that for power sources, the cathode and anode are marked opposite to that of diodes and other electronics. In them, the cathode is the positive terminal and the anode is the negative one.

Here’s a list of all the tools you’ll need to build the DIY Rotating LED Clock Display. Each tool links to Amazon. If a link isn’t available, we’ve included tips on how to find another one.

Here’s a list of all the parts you need to build the DIY Rotating LED Clock Display. Each part links to Amazon. If a link doesn’t work, don’t worry - we’ve also added tips on how to find a replacement.